3D BIOPRINTING MAIN AREAS OF IMPACT

Drug testing and discovery

The journey of bringing a new drug to market is long, expensive, and challenging. On average, thousands of compounds are screened during the discovery phase, but only one is approved. Recent estimates suggest that pre-launch R&D costs range from $161 million to $4.54 billion (2019 US$). These staggering figures underscore the urgent need for more accurate and cost-effective drug screening models. Enter in vitro 3D tissue models—innovative alternatives to traditional 2D cell cultures and animal testing. These models mimic the histological structure and functional activity of human tissues, offering a more reliable platform for evaluating drug efficacy and safety.

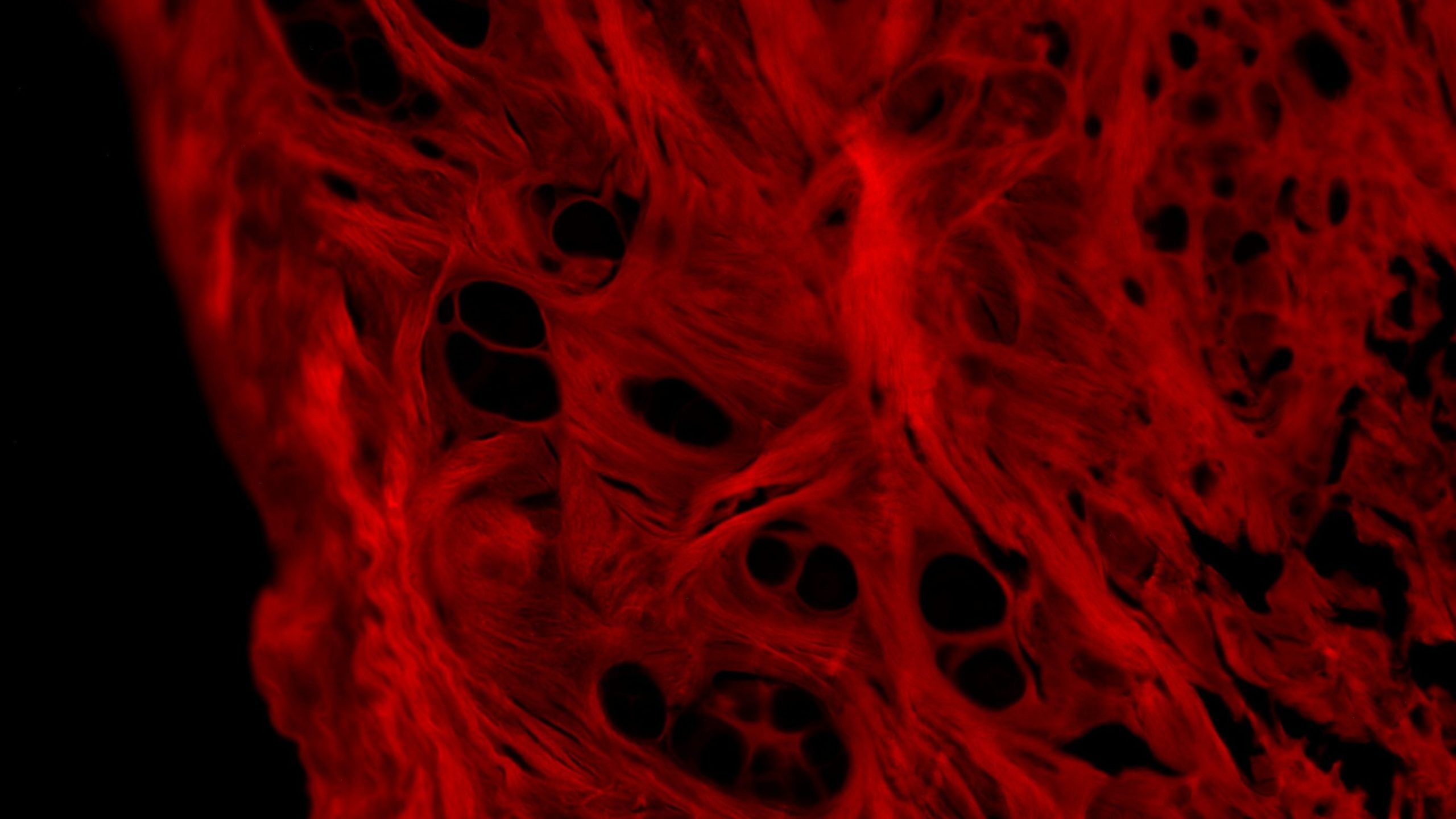

Regenerative medicine

Regenerative medicine is a cutting-edge field focused on harnessing the body’s intrinsic healing mechanisms or replacing damaged tissues with functional alternatives. This multidisciplinary domain spans from stem cell therapies to bioengineered. At its core, bioprinting enables the precise fabrication of autologous blood vessels, heart valves, musculoskeletal tissues, cartilage, and skin, meticulously engineered to integrate seamlessly with the patient’s physiology.

Personalized medicine

3D bioprinting emerges not only as a technological marvel but also as a catalyst for redefining personalized medicine. Beyond its traditional applications, this groundbreaking technology pioneers’ new fields and offers transformative solutions to complex medical challenges.

Wound healing

Regenerative medicine is a cutting-edge field focused on harnessing the body’s intrinsic healing mechanisms or replacing damaged tissues with functional alternatives. This multidisciplinary domain spans from stem cell therapies to bioengineered. At its core, bioprinting enables the precise fabrication of autologous blood vessels, heart valves, musculoskeletal tissues, cartilage, and skin, meticulously engineered to integrate seamlessly with the patient’s physiology.

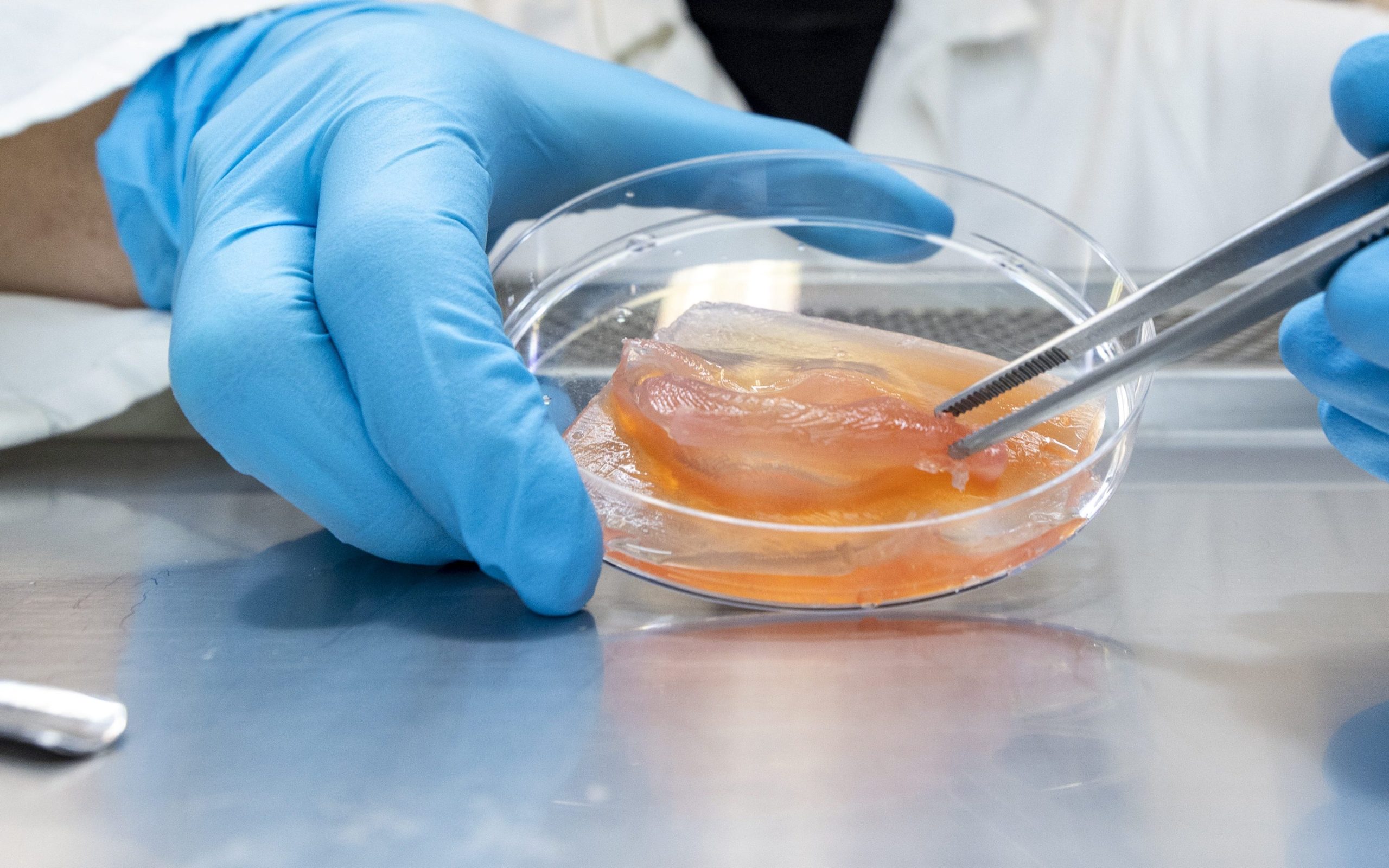

Lab-grown meat

Imagine enjoying a delicious steak that was created without harming the environment or involving traditional livestock farming. This future is becoming a reality through the advancements in 3D printing technology, which has been evolving since the 1980s. It began when researcher Robert J. Klebe used an inkjet printer to print cells, and today, this innovative method is being applied in the food industry.

While 3D-printed meat is not yet available for mass consumption, its development is progressing rapidly. In the near future, 3D-printed meat products may be seen in restaurants and eventually in supermarkets. This technology promises to revolutionize the way we produce and consume meat, offering a sustainable and nutritious alternative to traditional meat production.